Beverage Industry Machine

The beverage and liquid food sector has become a rapidly growing and very dynamic market in the recent years. The beverage packaging sector is developing rapidly in our country and in the world. The necessity to be hygienic in particular made it obligatory for the beverage industry to move quickly into packaged products. Especially water, milk, honey, ketchup, mayonnaise, mustard, salad dressing, olive oil, cream, barbecue sauce, butter, energy drink, fruit juice, yogurt, fruit yogurt, vinegar, lemonade, tomato paste, oil, fish oil can be filled and packaged without any contact and with all kinds of liquids and semi-liquids, especially with liquid products such as jam, marmalade, orange juice, fruit juice, vitamin drink and tang. High speed and high efficiency liquid filling machine systems can meet the needs of our customers. As Turpack Industry, we maximize the packaging machine quality standards of the food and beverage industry. Our packaging machine portfolio for the beverage industry consists of three types of machine groups. One of them is the stickpack group for disposable liquids and semi-liquid products, the other is the vertical filling group that produces the larger package, and the third is the powder filling machines that are added to the beverage by adding water afterwards.

Filling machine types for the beverage industry

1 – Disposable sticks liquid packaging machines

Single serving of yogurt packaging is usually packaged with liquid stick machine. Stick type machines are specially designed machines which can fill liquid food into stick packaging. Especially sensitive products such as chocolate cream, yogurt, fruit and cream are filled without any problems. It is designed according to the high-level hygienic requirements of our customers. Thanks to its fully automatic high technology, it can be produced without been hand touched. All settings are made from the touch screen. The production speed is fast because it is multi-lane. Thanks to the weight adjustment, different quantities can be filled. With the automatic cleaning system, the machine is transferred cleanly the next day. Optional features such as date printing system on the package, tear notches can be added aswell. All parts that come into contact with the product are made of stainless SS316 on our stick machines as in all our machines. It is a machine especially designed for the food and pharmaceutical industry.

Automatic feeding systems are used in such machines. One ton of large volume tanks on the floor is supplied to the machine by pumps. The pumps communicate via the sensors installed on the machine.

Working principle of the machine

The foil placed on the back of the machine is feed through the collar or forming plate of the desired width. The top and bottom sides of the packages are sealed with horizontal jaw, the back side or fin seal is closed with the help of hot vertical jaws as well. The product is filled with the pressure of the piston which inserts the product into the package that has already been formed as a stick. The top of the package will be sealed with the horizontal jaw after the product filling is completed. At the same time the horizontal blade system cuts the package and finalizes it. According to the desired consumption capacity, we can produce packaging machines from 3 lanes filling and packaging machines upto 10 lanes filling and packaging machines.

2 – Disposable stick powder packaging machines

Stick powder packaging machines also produce the same package form as stick liquid machines. The only difference is that the product is dust, not liquid. Although this difference may seem small, it has a complete different filling unit on the machine and its filling tubes. Stick powder products are granular and powdered products which are packed into the package of the desired weight and into the package of stick type. The working principle is almost identical to that of the stick liquid and the pump is used instead of a auger automatic feding system. Dusty drink products mostly, tang powder drink, orange powder drink, lemonade powder drink, powder coffee can be packed on the stick packaging machines.

3 – sachet machines in the beverage industry

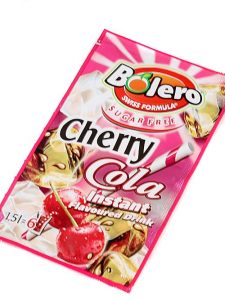

The only difference of single-use sachet powder, granule and liquid machines which is separated from the stick type powder and liquid packaging machines described above is that the package shape is different. The package shape is a package called (sachet) sealed on all four sides. This package shape causes the packaging to be produced on the machine with a different system from the film roll to the jaws. For this reason, sachet type machines and stick type machines are separated from each other and it is not possible to make the two package forms on the same machine. Sachet type packaging machines, liquid, powder and granule products are filled and packed. The first thing that comes to mind is the Tang powder beverage sachet packaging machine. Examples include Tang, Nesquick, Vito, Stingo, Bonero powdered drinks. Liquid, powder and granular beverage products are transformed into three separate machines on the sachet machine with three different filling units. Sachet powder beverages filling and packing machine, sachet liquid beverage filling and packing machine, sachet granule beverage filling and packing machine. Sachet powder and granular filling machine are separated from each other as filling techniques. If the powder product is in the form of a fine powder, which is not in a flowing state, its filled with augers but if the product is free flowing and granular then augers are not required.

4 – Vertical packaging machines

Vertical packaging machines are also known as bul kor kilo filling machines. Reason for it being called Kilo filling machines is because the machines has the ability to fill & pack from 50 grams to 5000 grams. Technological and design changes should be made on the machine due to the fact that it is filling and packing at higher volumes in terms of weight and the volume compared to our other machines is much higher. This change took us to vertical filling and packaging machines. Powder and liquid products can be packed in vertical machines.

Milk and liquid packaging

For example, if you want to fill 1kg (1000gr) of dairy products into pouches, the vertical filling machines is the machine that will meet your request. 1 kg of liquid milk filling and packaging material together the cost of a cheaper package is possible. In addition to the cost of plastic packaging in cardboard packaging, there is also a cost difference in relation to the cardboard packaging machine to the plastic packaging machine. Here, a manufacturer who wants to fill milk or other liquid products in plastic packaging will have a very suitable production due to both the cost of packaging and the cost of the machine. In addition to filling milk in our vertical liquid machine, mayonnaise, ketchup, mustard, water, vegetable oil, margarine oil, etc. can be filled.

Turpack machines are multilane and the production speed is high. The price is kept economical according to the quality we offer to our customers. It provides high efficiency with its compact design and fully automatic operation principle. It can fill multiple types of products smoothly with flexible adjustments and weight changes. In all of our machines, materials such as high quality electronics, pneumatic and other sensors are used. All of our machines are manufactured to work 24 hours a day. All the settings are highly precise which are controlled by the touch screen. Our standard designs as well as the new designs are made in high quality.

For more detailed information about the machines details which we produce for the beverage sector, you can contact us by filling the form on the relevant machine page, the form on our contact page, email address or by telephone. We would like to offer the most suitable solution or project according to your demands.